[Image of Eldorado removed]

A 1972 Cadillac Eldorado was a beast of a car. Eighteen-and-a-half feet long, it weighed in at over 2.1 tonnes and was powered by an 8.2 litre V8 engine. Shudder as you imagine the fuel bills.

And how much power did this mighty engine generate? A piddling 238 bhp, meaning the Caddy limped to 60mph in just under 10 seconds.

Fast forward 50 years and we have the Mercedes AMG A45 hatchback: its 2 litre engine produces 415 bhp, getting you from 0 to 62mph in an eye-watering 3.9 seconds.

So how have modern engines managed to squeeze out much more power – whilst at the same time getting smaller?

We’re glad you asked, and over this two part post, we’ll try to answer.

Catch up on combustion

To understand what’s going on, let’s first review the basics of what happens in a petrol combustion engine.

When you hit the go pedal, petrol and air are supplied into each cylinder, compressed, and ignited with a spark. The mixture burns rapidly, producing a large volume of gas, which pushes on a piston. The push from the piston is turned into rotational motion by the crankshaft, which in turn drives the wheels. After the fuel and air mix has burned, the exhaust gases are removed, and the cylinder is supplied with more fuel and air. The timing of this ‘cycle’ within the cylinder is precisely coordinated with the others, so that force is optimally applied to the crankshaft.

All this means that, apart from the size of the cylinders, there are several other factors affecting how much power an engine produces:

- How much air can be supplied to the cylinder

- How much petrol can be supplied to the cylinder

- How well the ignition can be timed for optimal power.

- How much the fuel and air mix can be compressed

- How efficiently exhaust gases can be removed

- How much friction forces can be reduced

Improvements in all of these have allowed modern engines to outperform their older counterparts. Taking them one by one:

1. Turbocharging

Photo credit: Bobbobson , via Wikimedia Co

Turbos have been around since the early days of internal combustion engines, but it wasn’t until the 1970s that they came into their own. at least in the USA. Over here, it took a little longer. Swedish superstars Saab were early to the game, and turbos had become far more widespread by the 1990s.

Turbocharging enables more air to be delivered to the cylinder. When that’s matched with more fuel, the engine’s performance goes through the roof. In fact, turbo-charging typically increases the power of an engine by 30-40%.

How do turbos work? A naturally aspirated engine (non turbo) sucks in air at atmospheric pressure, limiting how much oxygen is available for combustion. By contrast, a turbo uses the exhaust gases from the cylinder to spin a turbine wheel. This in turn spins a compressor wheel, which forces air into the engine at greater pressure. Greater pressure means more oxygen for combustion, which means more bhp per litre.

Still, that’s not the only way to add power, and some manufacturers (stand up, Mazda) prefer other methods.

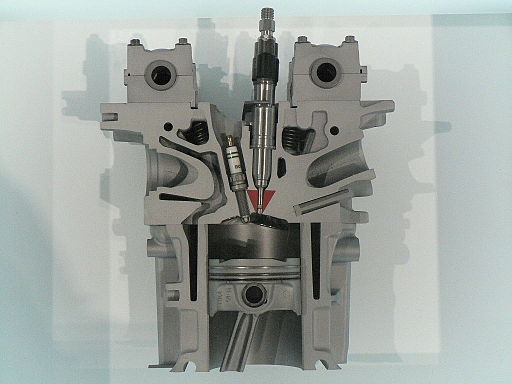

2. Fuel injection

Ton1~commonswiki, CC BY-SA 3.0, via Wikimedia Commons

The other substance needed for combustion is fuel. Years ago, the standard means for supplying fuel to the cylinder was the carburettor. Essentially, this used mechanical valves to mix fuel and air into the correct ratio, before feeding it into the cylinder. It’s a simple, elegant bit of engineering – but it’s also pretty inefficient.

Modern engines largely eschew the carburettor in favour of fuel injection, where fuel is squirted directly into the cylinder. This allows a much increased fuel flow. According to automotive writer Nina Russin:

In the 1960s, a typical fuel pump delivered 8 to 10 psi to the carburetor. Pressures in today’s direct injection fuel systems average about 2,000 psi. (That’s not a typo.)

In addition, the proportion of the fuel/air mix is now controlled electronically. Sensors detect exactly how much fuel is flowing, and the Electronic Control Unit (ECU) does a bazillion calculations to optimise the mix. It all adds up to greatly increased fuel efficiency, and again more horses per litre.

We’ll pick up on the other power-boosting techs in Part Two – see you in a fortnight!

The WVS blog covers a wide range of automotive topics, from the contentious to the light-hearted. We are an independent garage specialising in all the VW group marques, including Audi, Volkswagen, Skoda and SEAT. WVS provides services, repairs and MOTs, delivering a main dealer level of care at affordable prices. To book your vehicle in, or for any enquiries, get in touch.